Supporting global EV battery makers with top-flight project management

〜Overseas projects to set up EV battery plants〜

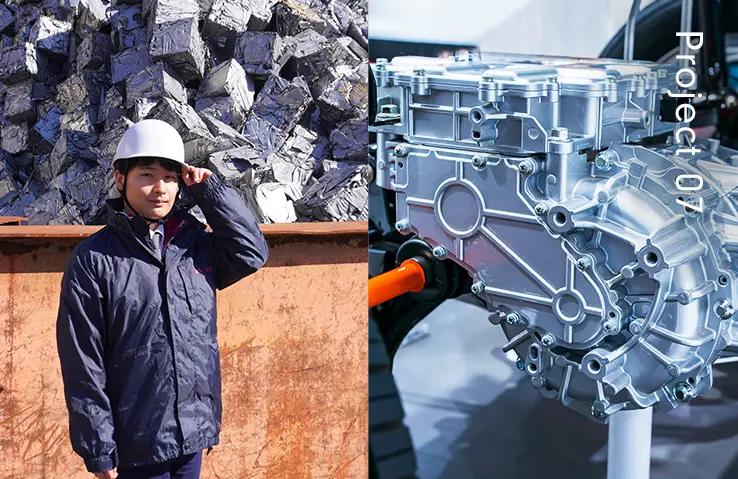

Makoto Toju, General Manager

Machinery Division Plant Equipment 2 Group

- #CarbonNeutral

- #Environment

- #Diversity

- #ProblemSolvingPower

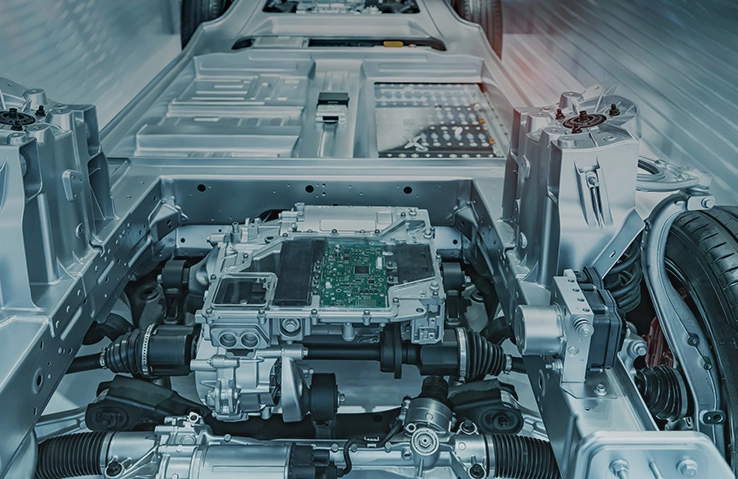

EVs underpin decarbonization. We are helping to expand and increase battery plants

In an age of accelerating efforts to achieve carbon neutrality, the key held by the automotive industry is the transition from gasoline to electric. The International Energy Agency (IEA) forecasts that the number of EVs on the road will reach 250 million in 2030 and 525 million in 2035. More than one in four vehicles on the road worldwide are expected to be EVs in 2035.

Around the world, carmakers and battery manufacturers are building factories and boosting battery production to meet the burgeoning demand for EV batteries. AESC, one of the first companies to produce lithium-ion batteries for EVs in the world, is currently planning to expand its plants and build more to increase battery supply.

When Nissan established plants in Japan and the United States to make the batteries for the Leaf, Nissan Trading Co., Ltd. (NITCO) was responsible for the transportation and installation of the production equipment, as well as the start-up of the site. I have been involved in overseas projects like this for more than 20 years and back in 2010, I was managing a site in the US as an expat employee.

AESC has bought into the experience and track record of NITCO, and they requested our support to build global hub factories. The first step is building a pilot production line at the Ibaraki plant in Japan. We have been involved from the planning stages, proposing a solution for an overall project scheme plan and division of roles. We have also been contracted to transport the production equipment and install it at the plant, our specialties. I have been assigned as the overseer of the project.

Guaranteeing the quality of factory equipment by managing the foreign manufacturer

The difficulty of the Ibaraki plant project was the process of adopting the new production equipment. In this case, much of the production equipment to be installed in the plant was imported from China.

Meanwhile, on the other side, the Chinese manufacturer supplying the production equipment had almost no experience of exporting. They were worried about their lack of know-how in terms of exporting and trade. That is when we came in and built our relationship with them from zero and provided support to them, scrupulously sharing methods related to export trade, such as how to prepare documents and how to make shipments.

A particular difficulty was that Japan and China have different habits when it comes to logistics and production equipment packing, so we were constantly having to revisit things. In the case of a Japanese manufacturer, we carry the equipment from the manufacturer to a packing area near the port and pack everything at once there. In China, the equipment manufacturer usually does their own packing at the factory, which would eliminate NITCO’s window for checking the quality of the equipment before packing. As such, for this project, NITCO opted to take the lead at the port and change the flow to do all the export packing there, in careful consultation with the manufacturer.

Here we needed to conduct export packing of a large volume of goods in a short period of time, so in the end we set up a warehouse at the port in Shanghai to make the packing as efficient as possible. There we checked each piece of equipment brought in, shipping only items without issues. This meant that our defect rate was zero.

Experience of diverse workplaces a feather in the cap for expat staff

The 1,500 containers of production equipment we installed at the Ibaraki plant was the biggest shipment by volume I have ever seen. At peak, there were 50-60 containers arriving at the Shanghai warehouse every week, and we were loading 20-30 containers on ships, which come in twice a week.

Shipments arriving at Yokohama port were then loaded on trucks by our contractor and taken to Ibaraki, then installed in the plant under the eagle eye of NITCO. Nobody in the industry has much experience of installing Chinese battery manufacturing equipment at a factory in Japan, so we had to use our wits to install it safely and efficiently, given the insufficient information we had received in advance.

As if to praise our work on the project setting up the Ibaraki plant, AESC then asked us for support again for their plant in the United Kingdom. This was one of the top two hardest overseas projects I have ever experienced, because British safety rules are even stricter than Japan’s. Our local team is working together with the contractor to work out how to efficiently install production equipment without breaking the rules, as different as they are from the ones in Japan.

The UK project team consists of staff of more than ten nationalities, so it is very diverse. There is nothing simple about successfully completing such a challenging project, while ensuring smooth communications among the different team members. Yet as management, we anticipate that expat NITCO employees will find this to be a tremendous opportunity for growth.

Managing overseas project take a lot of work and pressure, with one unanticipated incident after the other, as noted above. Yet, the sense of accomplishment upon completion is equally great. It is a very rewarding job to be able to see the results of your own efforts as a new facility takes shape where yesterday there was nothing, then to be there as the plant gradually nears completion.

On site today to train the personnel who are the future of the EV transition

Both projects presented here are very large and at first, I thought would not be possible to achieve with the staff of my department alone. So, I consulted with management and the HR department and established a new internal recruitment system called the “trainee system” to bring in staff from other NITCO departments in Japan and China. I was delighted to find that excellent staff working in the company were applying, thinking to themselves, “I would like to try out a hands-on role”.

Considering the rise of EVs going forward, current global battery manufacturing capacity is completely inadequate. AESC is also planning to build new battery plants. It is our urgent task to develop human resources able to manage overseas projects to meet growing future demand.

Nevertheless, overseas project management is not a job that lends itself to following a manual. Every project site is unique and unanticipated events are constant. You need be the driving force of the project, responding to situations with resourcefulness, in collaboration with stakeholders. The ability to drive a project forward can only be developed though experience across a range of sites. For this project too, we have placed a lot of staff on site, both young and veteran. Personally, I show up on site as much as possible to share my knowledge and know-how.

The ability to manage exporting of production equipment for a Chinese manufacturer on a project of this size is a unique strength of NITCO. We are harnessing the know-how we have developed to support battery plant expansion, key to the EV transition – while fostering talent capable of global success. I believe that is a major mission for us if we are to contribute to a carbon neutral world.

Related Business Divisions

Machinery Business

Nissan Trading provides value throughout our customers' Monozukuri lifecycle via the products and services that we handle, such as automobile-related manufacturing equipment, equipment transportation, and machine maintenance parts.