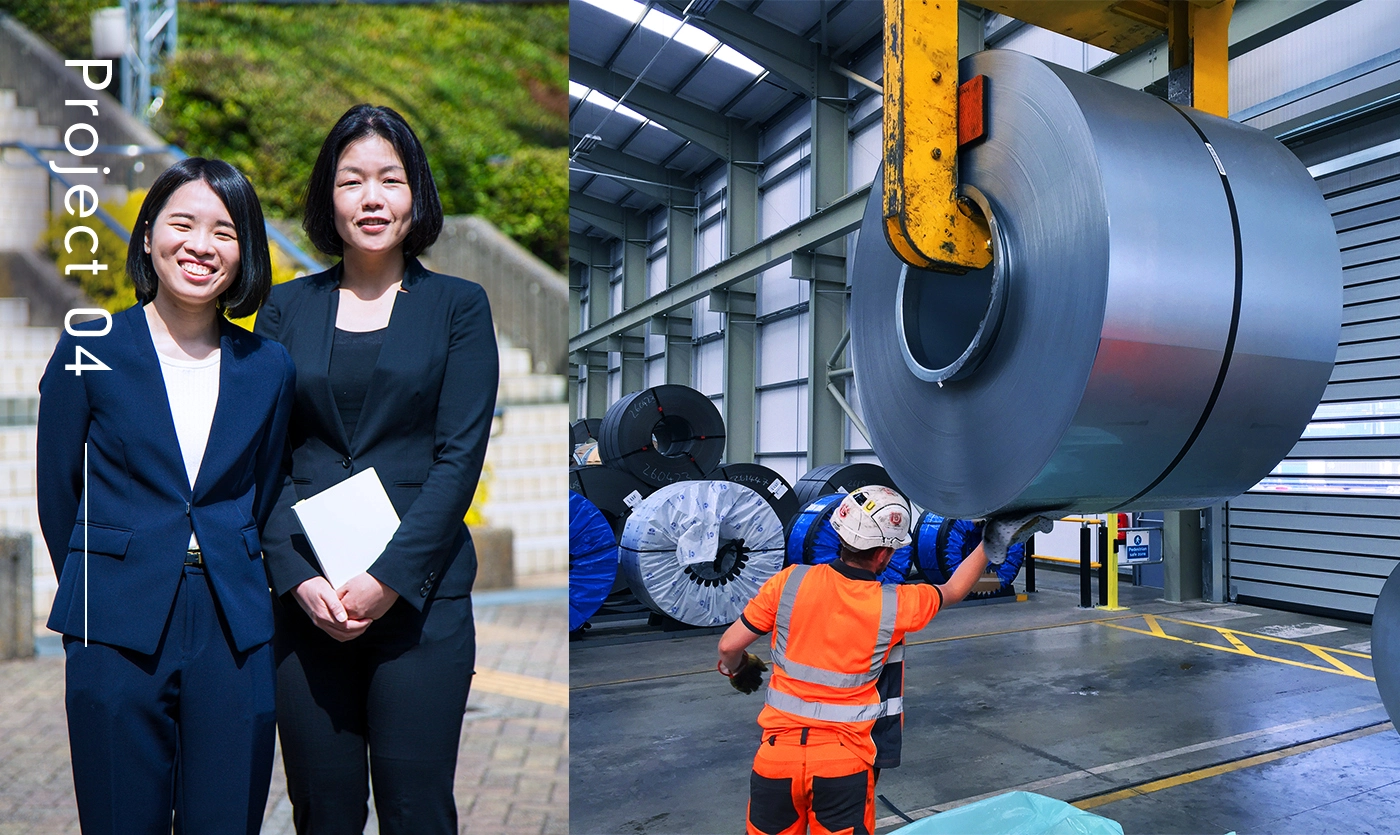

Procuring Trial Manufacture Steel Sheets for New Cars

from Major Steel Manufacturers Around the World

Global Material Division

Steel Group Steel Sheet Trial Manufacturing Team

Misaki Iwai / Chiho Imai

- #Diversity

Responsible for procuring, from all around the world, the steel sheets that will be the basis for prototypes

Nissan Trading (NITCO) undertakes the work of procuring, from major steel manufacturers all around the world, the trial manufacture steel sheets for new vehicles that will be launched at the Nissan Automotive's global locations. When a vehicle is going to be made overseas, Nissan creates the prototypes in Japan using materials from the country where the vehicle will actually be mass-produced. Therefore, as part of the Steel Group Steel Sheet Trial Manufacturing Team, it is our job to procure, from steel manufacturers all around the world, the steel sheets that will be used for those prototypes.

We currently have five people on the team. Each person is in charge of one project, and that person manages the delivery's progress, everything from checking the shipping information and customs documents to requesting customs clearance and delivery. (Imai)

Generally speaking our team simultaneously manages the trade and transportation of the various types of steel sheets used for massive parts, which is an extremely complicated job, but it plays a major role in laying the foundation for vehicles around the world. (Iwai)

How do you meet customer expectations when unexpected events or circumstances occur?

To begin with, it is unlikely that our work in the Steel Sheet Trial Manufacturing Team will proceed as expected. Currently, COVID-19 is causing disruptions in transportation infrastructure and supply chains around the world, and logistics always carries the risk of accidents or some sort of trouble. Because the parts manufacturers that make the prototypes are also undergoing a process of trial and error, there are often requests during our work to change the materials.

An order may be canceled when the parts have already arrived at the local port, or there might be worries about COVID-19 countermeasures. Trial manufacturing steel sheets are not a regular or standard job for steel manufacturers, so they may not be able to immediately produce sudden new orders. Amidst such unexpected events and difficulties like this, our team is working every day so that we can meet the expectations of our customers. (Imai)

A European new vehicle project that became an important experience

The first major job that I was involved in after joining the Steel Sheet Trial Manufacturing Team was a European new vehicle project. In order to do a full model change of the major European models, our mission was to procure materials from steel makers all over Europe and then deliver those materials on time to the Japanese mold and parts manufacturers.

Essentially, the individual overseeing the regional NITCO office will handle communication with the overseas steel manufacturers. Normally, in Japan, we communicate via emails or phone calls with the individual overseeing the regional NITCO office and confirm the shipping status, etc. of parts. Another important part of this job is to lay the groundwork for employees at the regional office of the Japanese shipping carrier that will be in charge of the transportation, such as by telling them that we are planning to ship out a certain amount of cargo in this time period and that we want them to start beginning preparations. We do this so that things go more smoothly, even if it's just a little bit more smoothly. (Iwai)

Going to the UK site to understand the confusion and sort it out

In addition to members of NITCO's regional offices, Iwai-san and I visited to the UK as dedicated specialists for this project, visiting suppliers and confirmed the status of each and every part-- whether it was in the UK, whether it was in transit, or whether it was awaiting delivery instructions after clearing customs. After that, we assigned priorities to them and created a management table, and then, based on that management table, made shipping preparations. Every day we were looking at the progress management table that we made in Excel. The cells for parts that had been delivered were changed to grey, and it was a pleasure to watch as, day by day, the entire table changed to grey. (Imai)

The experience of this big project became self-confidence and strength

From the first order until the final delivery, this project took approx. 1.5 years, but it was finally completed. I was happy that, without any problems, we were able to procure the steel sheets required by the manufactures and that we were able to contribute to the launch of the new vehicles. However, in this job we have unexpected things happen on a near daily basis, and we often receive complaints from our customers.

Even in this project, one of the things that occurred was that a product was not shipped according to schedule, and the items that actually shipped were different from the purchase order. In cases like this, it is important to properly and clearly convey not only the result, but also the process, such as explaining the situation and recovery plan to the customer. In this project as well, we had the opportunity to meet with customers every week, and we always tried to report and share the latest information. (Imai)

It was quite difficult at the time, but, by handling these large orders, in a short period of time I gained a lot of knowledge about what trading work is actually like. I have also extensively used that experience in the project that we are currently working on, the delivery of Russian trial production materials. (Iwai)

The pride of being involved in the global launch of a new vehicle is what nourishes our work

It seems like a given that logistics will move smoothly, and a major premise is that deliveries will arrive on time. Therefore, even if the Steel Sheet Trial Manufacturing Team desperately works to keep deliveries on time, that doesn't necessarily mean that we will be highly praised. Particularly now, amidst the COVID-19 pandemic, the utilization rates of overseas steel makers are decreasing due to lockdowns, etc. However, even in situations like that where we cannot do anything about it, we will do our utmost to make deliveries in the best possible way. Our members are proud of the work that they do every day. (Imai)

This job is just from order to delivery. But, more than that, I was deeply moved when I heard that a vehicle, made with the parts and materials that I had worked so hard to deliver, was released. Going forward, I want to become even better at my job, contribute to the rise of new vehicles around the world, and let many different people know about NITCO's abilities in the business of prototyping new vehicles. (Iwai)

Related Business Divisions

Material Business

For Nissan Motor and for the domestic and overseas plants and parts manufacturers of Alliance Group members Mitsubishi Motors and Renault, Nissan Trading contributes to improving the competitiveness of the Alliance Group and to achieving carbon neutrality through information management, environment-related businesses like material recycling and electricity sales, and through supply of automotive materials like steel products, raw materials, non-ferrous metals, and chemicals.